详细介绍

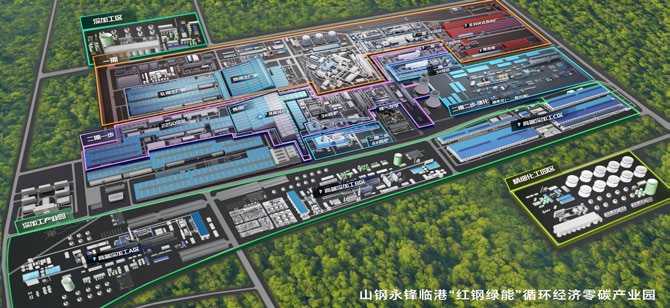

临港基地响应山东省新旧动能转换号召,打造焦钢化氢循环经济生态产业园。产品结构包括精品长材、精品板材和精品工业用材及品种钢。重点配套的2250mm热连轧生产线产品广泛应用于高端家电、汽车及新能源领域。依托产业和区位优势,全力打造“红钢绿能”循环经济零碳产业园。面对国内国际两个市场,正在积极拓展高强钢、冷轧等方面的深加工,进一步提升产品品质,形成差异化竞争。

投产以来,打造了冶金行业内第一个覆盖全流程的工业互联网平台,是国家级全流程智能制造示范工厂和国家卓越级智能工厂,是第一批多工序、多场景落地运用华为盘古大模型的钢铁企业,并与华为联合成立了临港数智钢铁创新示范建设中心;也是钢铁行业内第一家基于MA统一标识落地应用的企业;还是第一批被国家发改委纳入《绿色低碳先进技术示范项目清单》的钢铁企业。公司被麦肯锡认定为大中华区第1家、全球第2家开放线下精益见学基地,正在推进“数字化灯塔工厂”和“可持续灯塔工厂”打造,并且第一个以整个长流程“端到端灯塔工厂”来做。是行业内第一个人均年产钢量突破2000吨的民营钢铁企业。

The Lingang Base responds to the call of Shandong Province to transform old and new driving forces, and builds an ecological industrial park for the Jiaogang hydrogen recycling economy. The product structure includes high-quality long materials, high quality sheet materials, high-quality industrial materials and varieties of steel. The key supporting 2250mm hot rolling production line products are widely used in high-end home appliances, automobiles, and new energy fields. Relying on industrial and location advantages, we will make every effort to build a "Red Steel Green Energy" circular economy zero carbon industrial park. Facing both domestic and international markets, we are actively expanding deep processing in high-strength steel, cold rolling, and other areas to further improve product quality and form differentiated competition.

Since its operation, it has built the first industrial internet platform covering the entire process in the metallurgical industry. It is a national-level full-process intelligent manufacturing demonstration factory and a national-level excellent intelligent factory, and one of the first steel enterprises to implement Huawei's Pangu model in multiple processes and scenarios, jointly establishing the Lingang Digital and Intelligent Steel Innovation Demonstration Construction Center with Huawei. It is also the first enterprise in the steel industry to implement MA unified identification. Moreover, it is one of the first steel enterprises included in the Green and Low-carbon Advanced Technology Demonstration Project List by the National Development and Reform Commission. The company, recognized by McKinsey as the first in Greater China and the second in the world to open an offline lean learning base, is advancing the construction of "digital lighthouse factory" and "sustainable lighthouse factory", and it is the first to implement the entire long-process "end-to-end lighthouse factory". And it is the first private steel enterprise in the industry with per capita annual steel output exceeding 2,000 tons.